Products

Sheetfed Ink

High quality sheetfed Offset process printing ink

| Outline | Features |

|---|---|

| ROYAL-G Sheetfed ink is a product that shows stable quality in general art paper and high art paper printing workability. It is also suitable for advanced process sheetfed offset printing due to good dot reproducibility and mileage. Intense density and consistent color can be reproduced with Ideal product which is applicable to various types of printing materials and printing machines. |

|

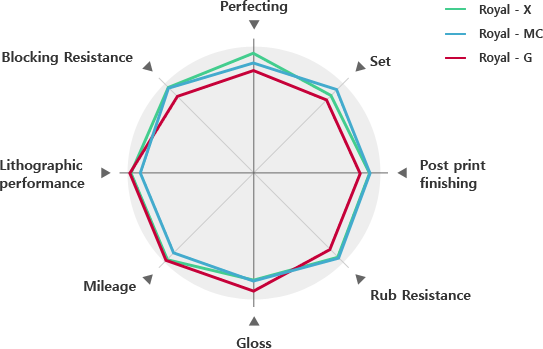

| 0(bad) - 10(good) | 0 5 10 |

|---|---|

| Perfecting | 9 |

| Set | 9 |

| Post print finishing | 8 |

| Rub Resistance | 9 |

| Gloss | 10 |

| Mileage | 9 |

| Lithographic performance | 9 |

| Blocking Resistance | 9 |

| Product name | Color | Type | Features | Packing |

|---|---|---|---|---|

| ROYAL-G | YELLOW |

H type N type S type |

High quality Gloss-Coated Paper Sheet-fed Offset Art paper |

1kg tin 12 cans in a box 1kg vacuum 2.5kg vacuum |

| MAGENTA | ||||

| CYAN | ||||

| BLACK |

H Hard N Normal S Soft

Scroll right to see more tables.

RESISTANCE

| Lightfastness | Alcohol resistance | Alkaline resistance | Foil Lamination Ability | UV Varnish Ability | Aqueous Coating Ability | |

|---|---|---|---|---|---|---|

| YELLOW | 5 | + | + | + | + | + |

| MAGENTA | 5 | + | - | + | + | - |

| CYAN | 8 | + | + | + | + | + |

| BLACK | 8 | + | + | + | + | + |

Scroll right to see more tables.

STORAGE AND PACKING

Only store the ink in a specified place at ambient temperature – ideally the temperature range should be 18 -25 ‘C.

1kg vacuum tin / 12 cans in a box

2kg catridge / 6 cans in a box

2.5kg vacuum tin / 4 cans in a box

200kg barrels

SAFETY, HEALTH AND ENVIRONMENTAL REGULATIONS

KMI inks are formulated based on EU regulations, EU REACH and for detailed information, please refer to recent GHS MSDS.

This data sheet is for information and reference when using KMI inks. It is correct to the best of KMI’s knowledge. No liability for any errors, facts or opinions is accepted. Customers must satisfy themselves as to the suitability of this product for their application. During application, performance of the product can be affected by various factors which are beyond the control of KMI, so it is highly recommended that a test print is made before committing to a production run. The information contained herein may be modified without prior notice.